UeAI.iWSM Weaving Site Management

Single/double-sided large circular knitting machine

Ribbing machine

Towel machine

Jacquard machine

Single management platform across multiple brand models.

No wiring ! Lower interference ! Quick installation !

Cloud structure.

Support mobile device.

Automatically record weaving machine situation, including errors, events and status via SMB.

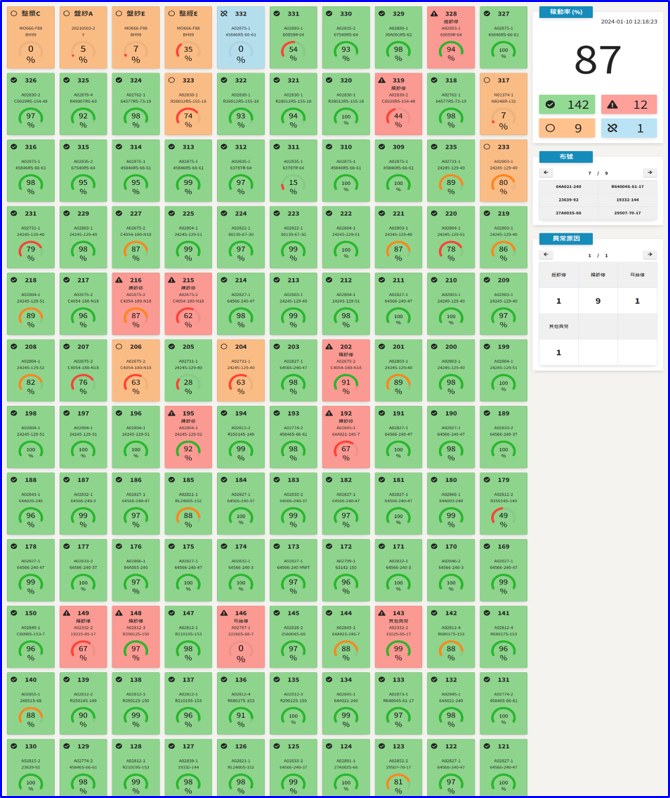

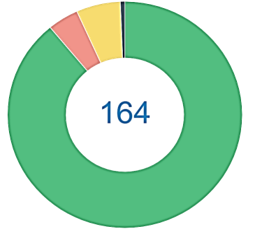

Quickly browse the dashboard according to the machine status which is provided from work area. Only need single person to manage multiple machines.

Report work jobs status and machine data with mobile device.

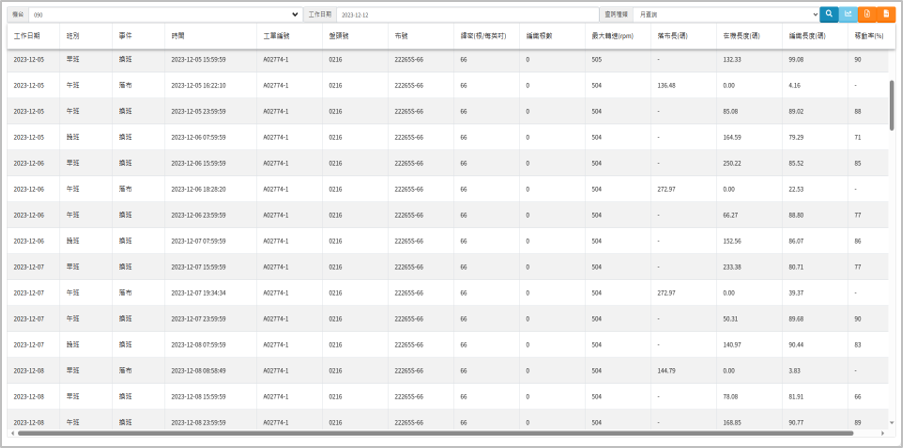

Calculate daily work shift report with classified list in produce amounts, efficiency and the length of the finished fabrics.

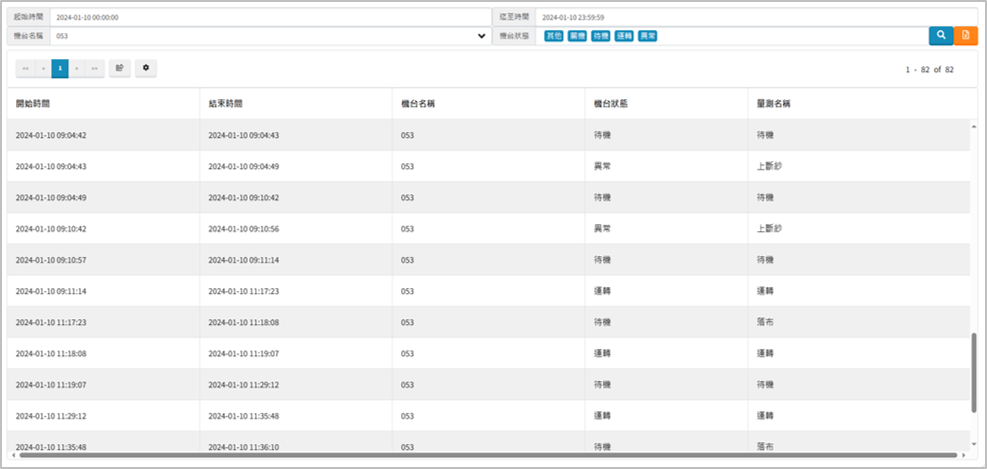

Easy to trace the Work In Process data to improve quality control capabilities.

Circular Knitting Machine-Digital Upgraded !

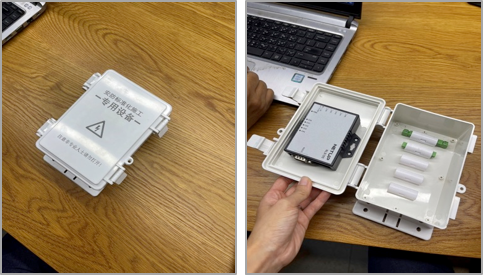

Installation SMB (NLS105*) with small size and lower power usage.

Supported quick-release connector. Easy to use and repair.

Supported LoRa wireless transmission.

Save infrastructure time via wireless construction required.

Real-time report with abnormal events, stitches and doffing information.

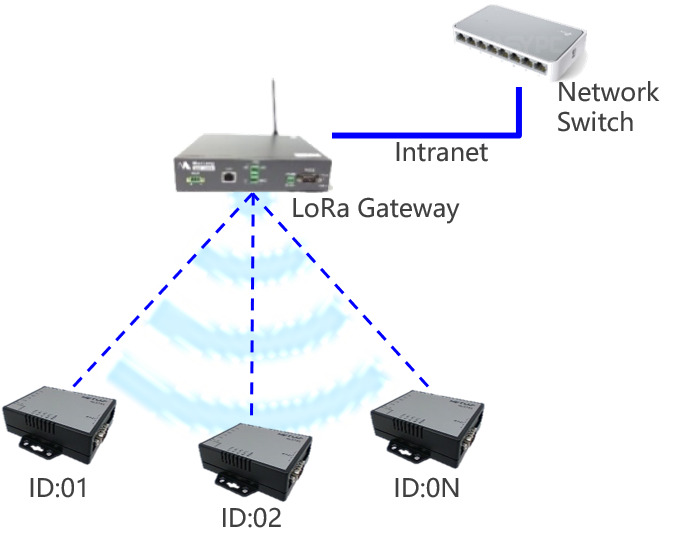

LoRa Network Configuration

Comprehensive system architecture with three-layers structures with LoRa gateway and smart machine box.

Support more than 20 smart machine box with single LoRa gateway.

Applicable to 868-928MHz frequency range in European and American IoT channels.

Up to 50 meters distance at Indoor.

Using the iWSM System

User Configuration Manager with role control

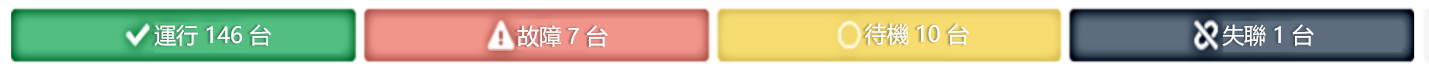

Quickly overview operation machine status.

Intuition color design among machine status.

WIP in Textile Work Order Information

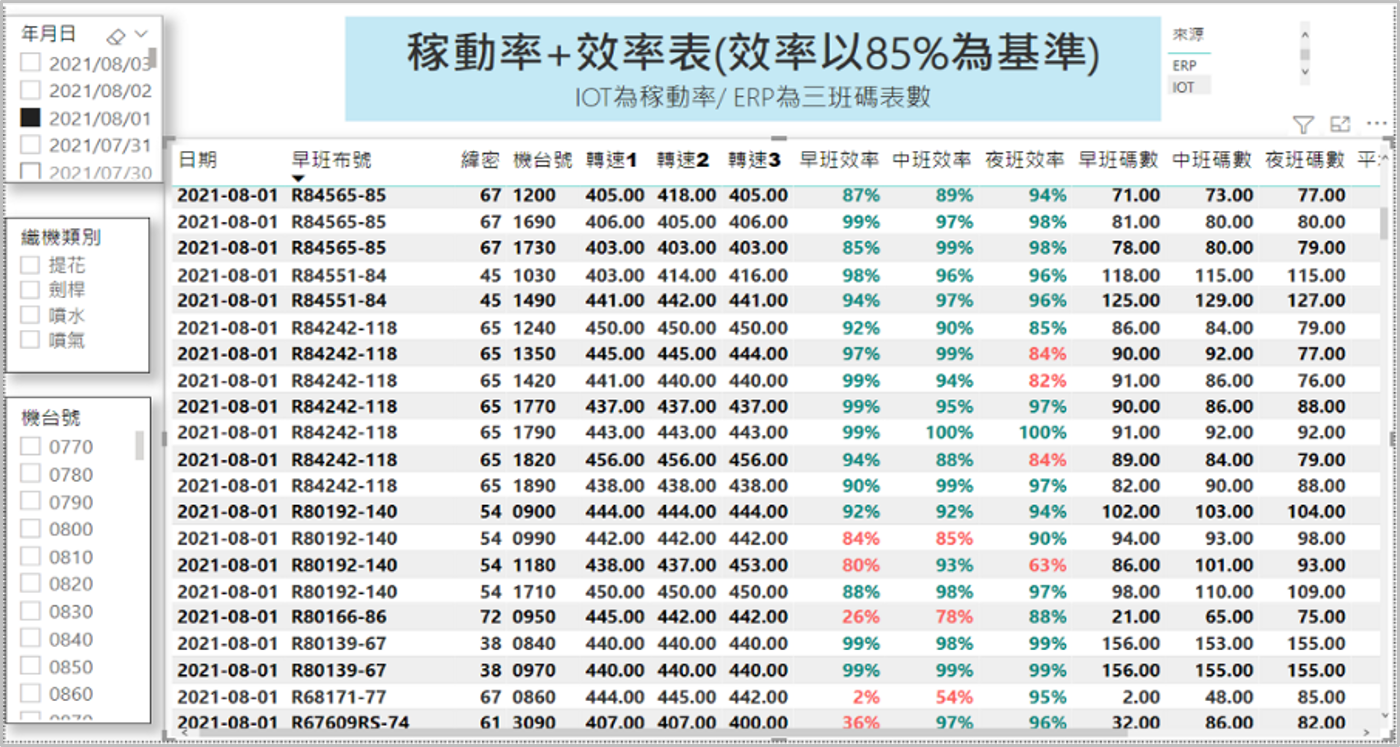

Daily work shift report to provide information with abnormal events, weaved length, rotational speed and doffing information.

Overview operation machine details / work information / number of machine shutdowns / machine downtime.

EAM loom Equipment Operation History

Ranked by production efficiency.

Minimize the troubleshoot problems and idle time.

Identifying major events of the machine / Reason for machine stop / Machine operation time...

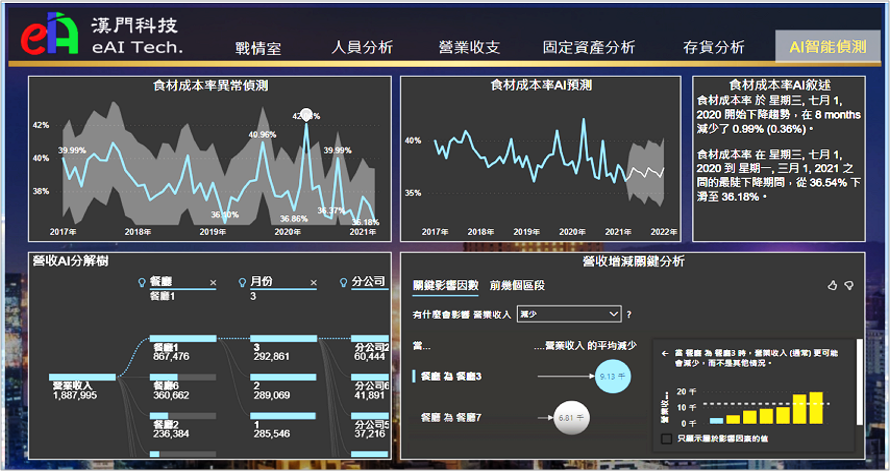

Additional Expanded Information Integration Services

Integrate with ERP system to connect work orders and customer information.

Rich charts: Enable enterprises to quickly grasp the situation.

Interactive operation: In-depth investigation of the source of the problem.

WEB mobile can be browsed instantly / Monitor machine status at any time and everywhere.

Data combines current status, history, analysis and forecasting.

DataFabric support to collect multiple system data such as ERP, MES, and IoT into data lake platform.

UeAI.iIOC Information Operations Center

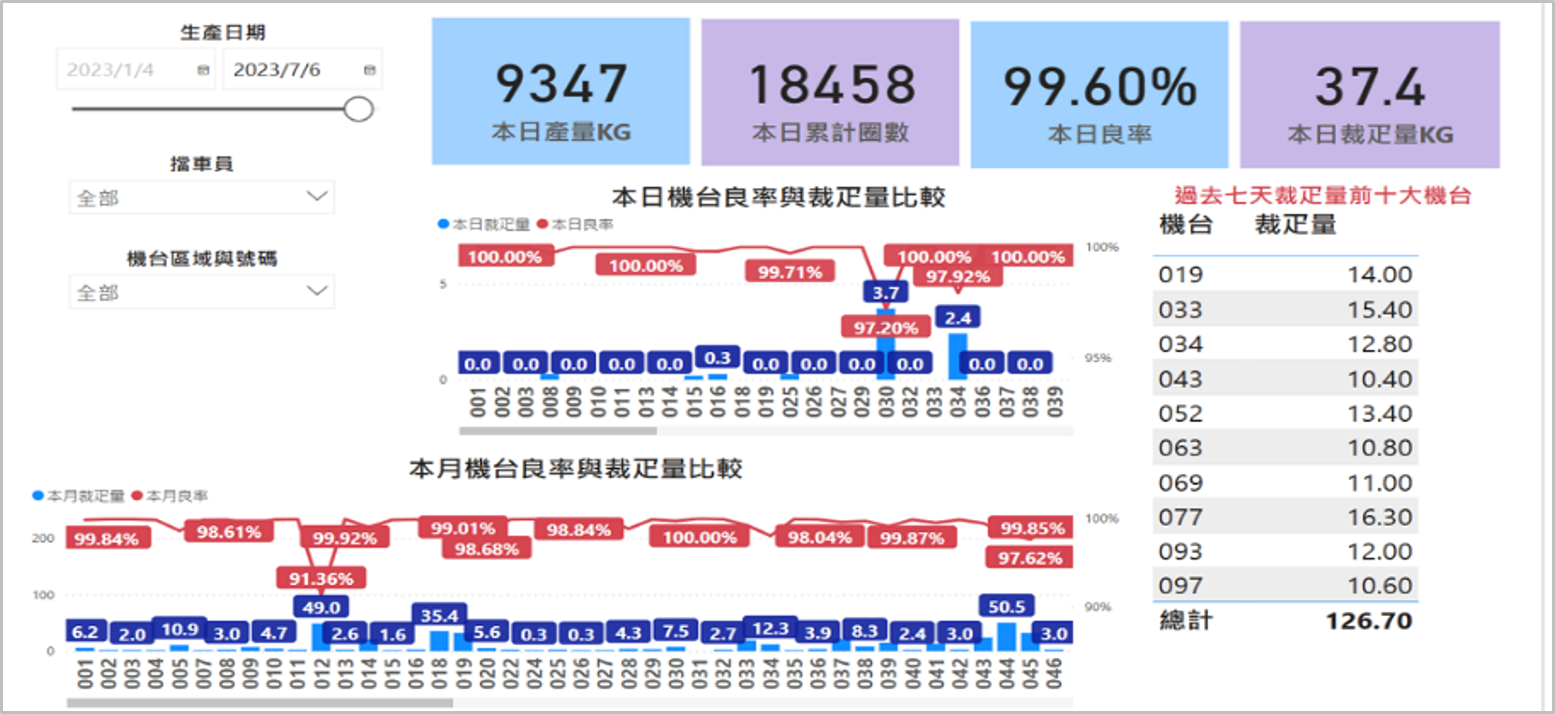

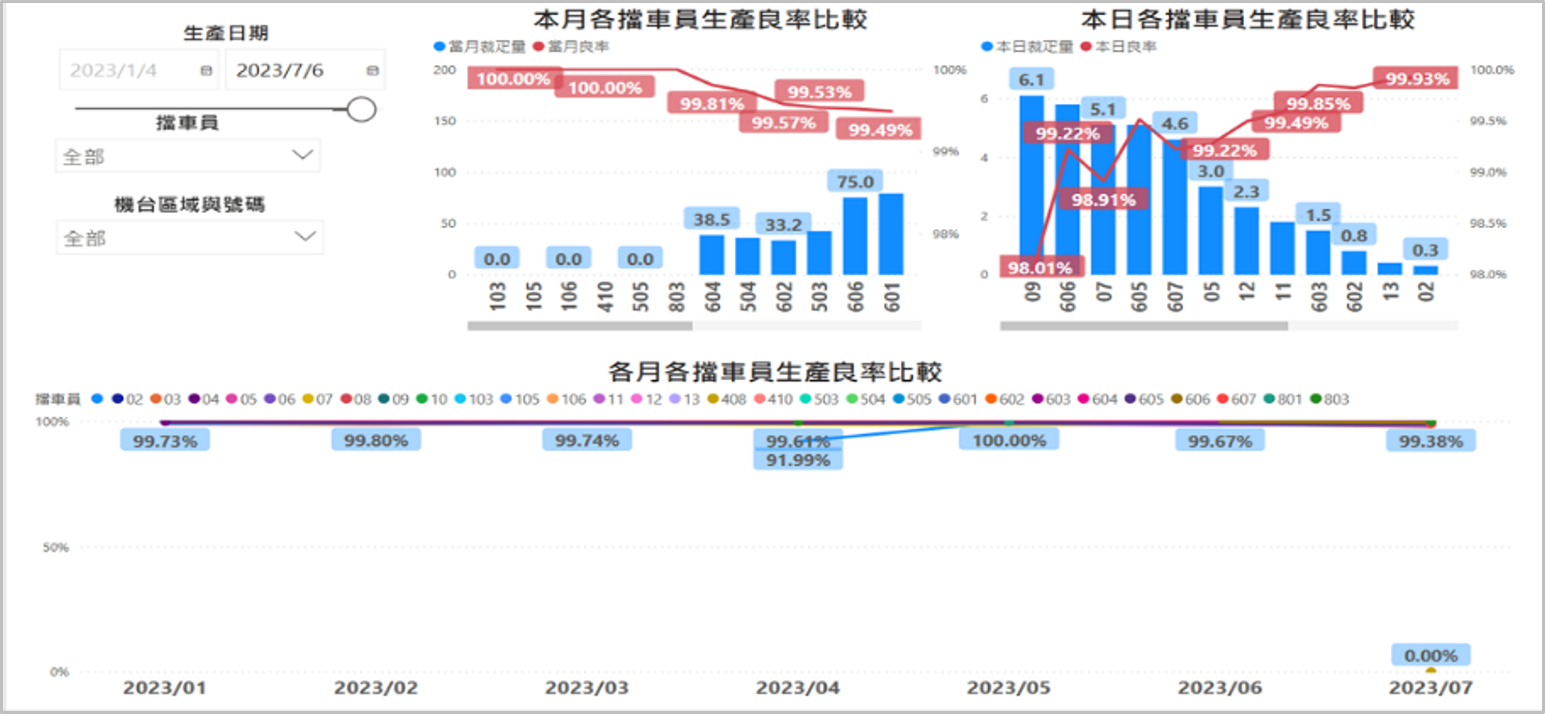

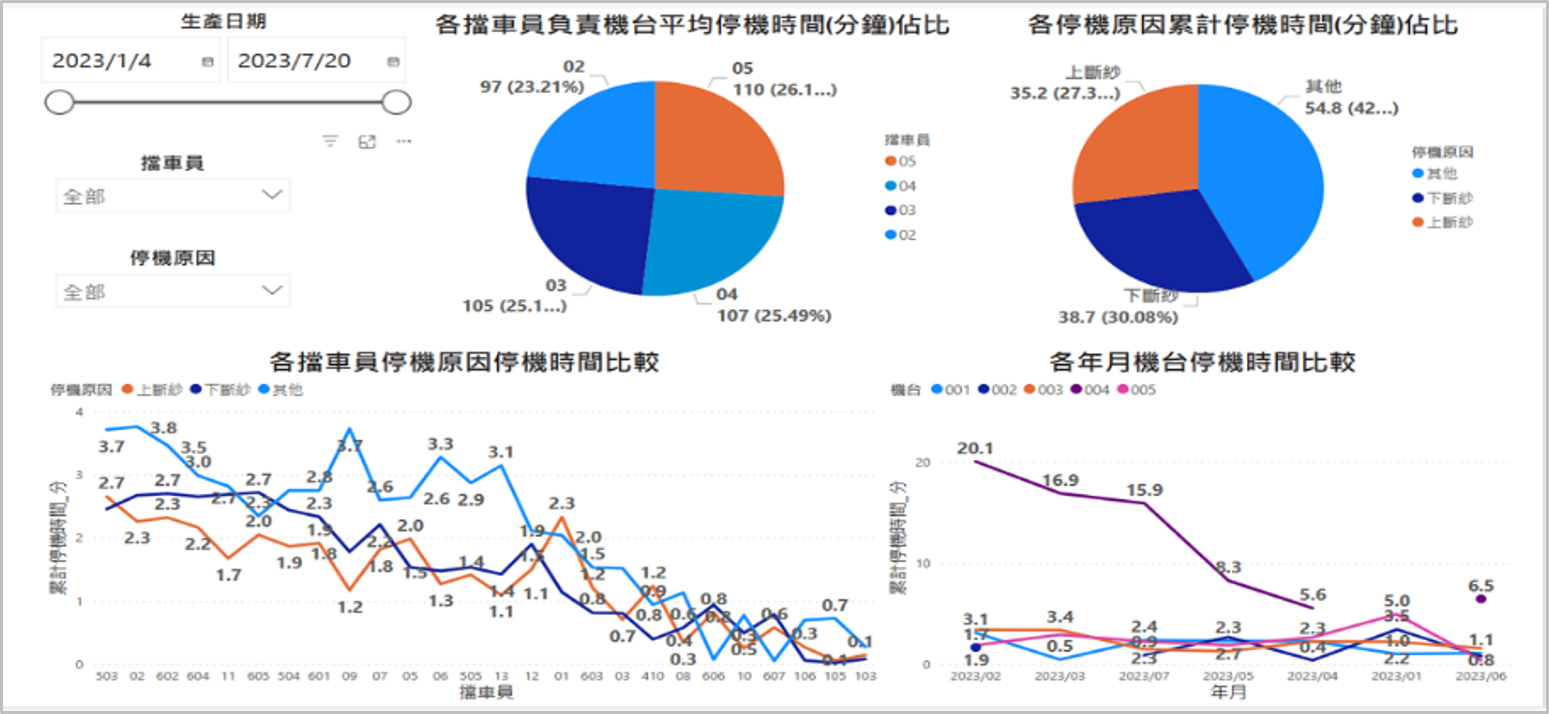

Producing efficiency analysis

Performance analysis of operator

Loom operation analysis and management

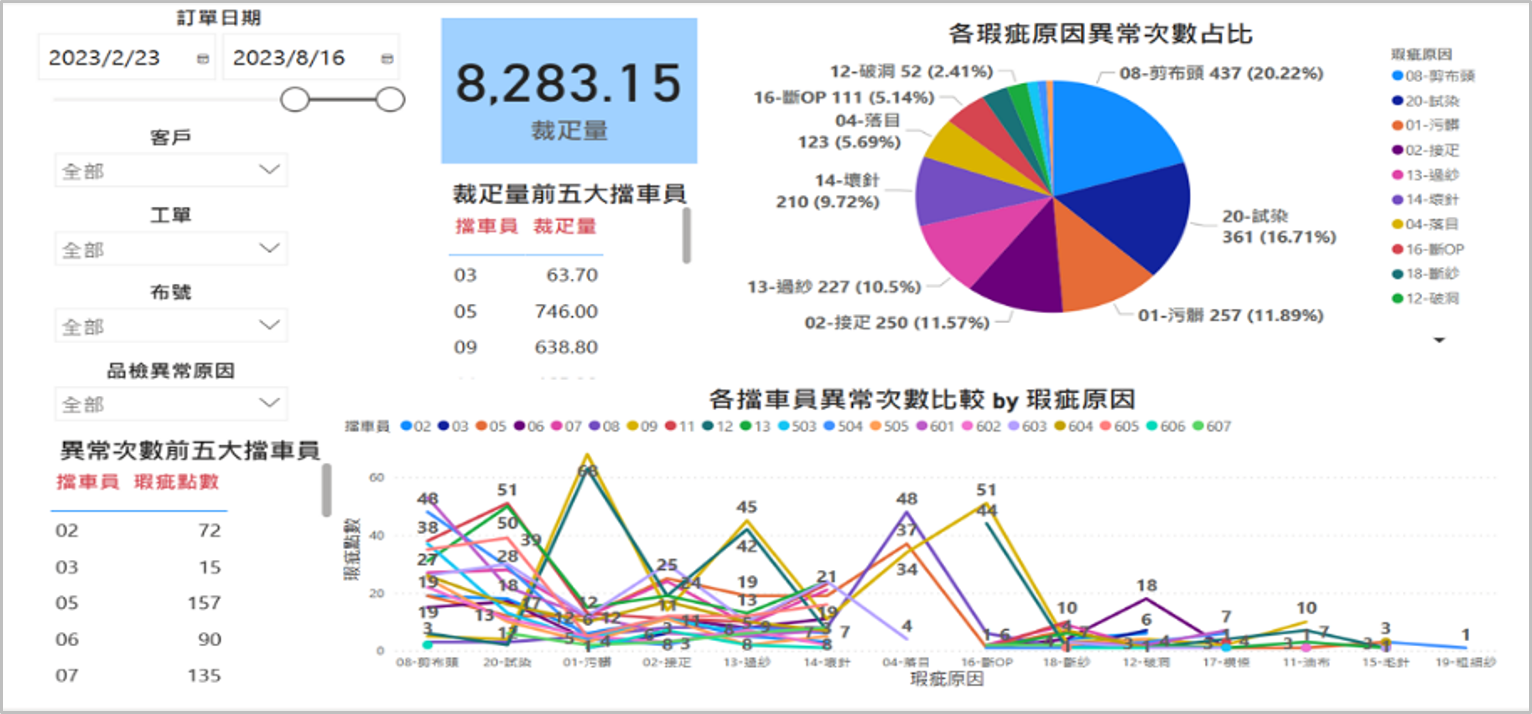

Quality inspection abnormality analysis

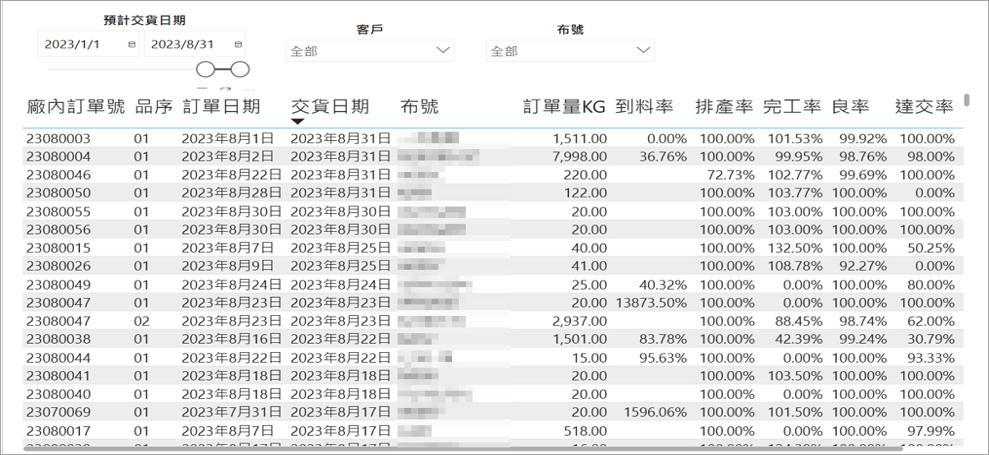

Work order production history

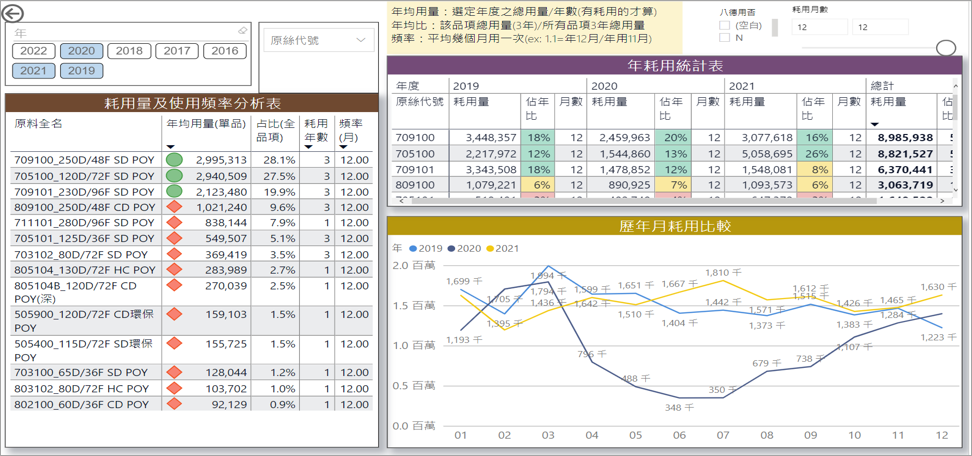

Analysis of raw material yarn usage

Production and sales progress tracking

Reference – SMB Specification

Product: NLS-105 Wireless IoT Device

Function:

① Collect and report on loom machine activities.

② Support to resume the transmission in the issue of network interruptions.

③ Easy to obtain the electric potential difference of the channel signal input changing state.

Input / Output port: 5 channels of digital input (DI)

1 RS-232 port (Functional limitations)

Communication Interface: LoRa(900MHz) * 1

Power: 5 - 24VDC 1Amp

Size: 102 * 92 * 25 mm

Weight: 100 g

Place of Production: R.O.C.(Taiwan)